IMOC installs PV plant-wide which can generate more than 800,000 kWh of electricity per year.

Built a new QD Lab.

Installed a solar panel system partially, upgraded the recycled water and wastewater systems, and planned to invest in SEM and complete new labs such as cleanliness, tin whisker, etc.

Finished construction of the new wastewater system, thermal cycle solar system, and achieved ZERO wastewater emissions.

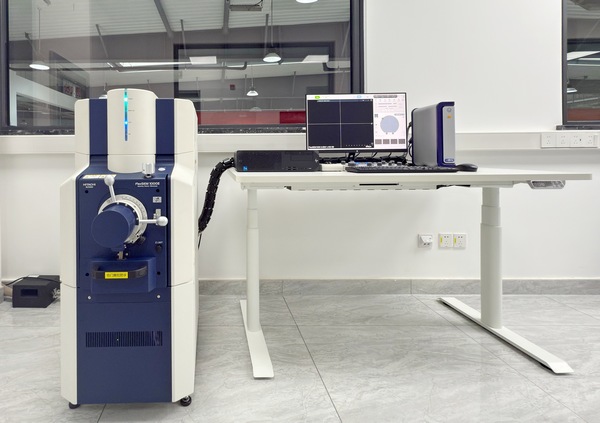

Built new plating lines in Phase 3 of the production hall. Invested in a press-in/out machine for the whisker lab and a new EDX machine.

Started construction of Phase 3 in the 3(rd) quarter.

The two production lines were approved by Bosch and Continental for mass production of silver-tin and indium plating, enhancing the bonding plating capacity and laboratory.

A new electroplating line was built in Phase 2 of the production hall, and the 'IMOC' trademark was registered in the EU and China.

Started construction of the Phase 2 of the production hall, and the sales office in European was founded.

Achieved ISO/TS 16949 certification in March, and installed the heat exchange system.

Achieved ISO 9001 and ISO 14001 certification.

The reel-to-reel continuous electroplating production line was put into use.

Foundation of the company.